3D Printing for Packaging: Transforming Prototyping, Small-Batch Production, and Customization

In recent years, the packaging industry has been undergoing a profound transformation. Packaging is no longer seen as a mere container to protect goods during transportation and storage. Instead, it has evolved into a vital part of brand communication, customer experience, and sustainability initiatives. This transformation has been fueled by technology, and among the most groundbreaking developments is 3D printing, also known as additive manufacturing. With its ability to create complex shapes directly from digital designs, 3D printing is reshaping how companies approach packaging design, production, and customization. It is helping businesses overcome long-standing challenges in prototyping, small-batch production, and personalization, while also aligning with sustainability goals.

One of the most significant impacts of 3D printing in packaging is seen in prototyping and design development. Traditionally, creating a packaging prototype required specialized molds, dies, or tooling. These processes often demanded considerable time and financial investment, making it difficult to test new ideas or iterate quickly on designs. For many companies, especially startups or those launching seasonal products, the barriers were too high. 3D printing has dramatically changed this dynamic by enabling rapid prototyping at a fraction of the cost. Design teams can now produce multiple prototypes within hours, test them for functionality and aesthetics, and refine them without the burden of long lead times or high upfront costs. This not only shortens the overall development cycle but also encourages creativity and risk-taking, as designers can experiment with shapes and features that would otherwise be impractical or too expensive to attempt.

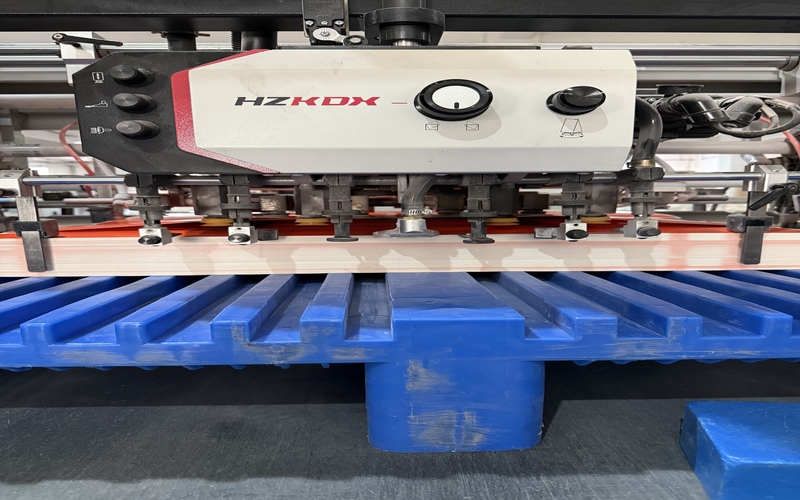

Beyond prototyping, 3D printing is revolutionizing small-batch production in packaging. Traditional manufacturing methods such as injection molding or die-cutting are highly efficient for mass production, but they are less cost-effective when it comes to small runs. The expense of tooling and setup makes it impractical to produce just a few hundred or even a few thousand units. This poses a challenge for companies that need limited-edition packaging, promotional campaigns, or packaging for niche markets. 3D printing offers a solution by eliminating the need for molds and enabling on-demand production. Businesses can produce packaging in the exact quantity required, without large inventories or excessive waste. This flexibility allows brands to respond more quickly to market changes and consumer demands, while also reducing financial risks associated with overproduction.

Equally important is the role of 3D printing in customization and personalization, two of the most powerful trends in today’s consumer landscape. Shoppers are increasingly drawn to products that feel unique or tailored to their individual preferences. Packaging is a natural vehicle for delivering this sense of personalization, and 3D printing makes it more accessible than ever. With additive manufacturing, companies can create customized packaging designs for specific customers, events, or product lines without the need for costly retooling. For example, limited-edition packaging for holidays, sporting events, or celebrity collaborations can be produced efficiently in small batches. More advanced applications may even integrate digital elements such as QR codes, embedded textures, or interactive features directly into the packaging. This level of customization not only strengthens brand identity but also creates a memorable experience that can drive customer loyalty and word-of-mouth marketing.

Another area where 3D printing is making a positive contribution is sustainability, which has become a major priority for both businesses and consumers. Traditional packaging often results in high levels of material waste, particularly when molds, dies, or excess stock are discarded. 3D printing, by contrast, is an inherently additive process, meaning it uses only the material required to build the object. This reduces waste significantly compared to subtractive manufacturing methods. Moreover, advances in printing materials are opening the door to more sustainable options, such as biodegradable filaments or recycled polymers. Localized production is another sustainability benefit, as packaging can be produced closer to the point of use, reducing transportation costs and emissions. For companies aiming to meet ambitious environmental goals, integrating 3D printing into packaging strategies can be an effective step toward greener operations.

The future potential of 3D printing in packaging is vast, though challenges remain. Currently, production speed and scale are limiting factors, as most 3D printers are not yet capable of matching the throughput of traditional high-volume manufacturing. However, innovations in printer technology are rapidly addressing these issues, with new systems being developed that offer faster printing speeds and larger build capacities. As these technologies mature, 3D printing could become a practical option even for medium- to large-scale packaging runs. Additionally, continued research into advanced materials, including stronger, more flexible, and more sustainable options, will expand the range of applications in the packaging sector. Integration with other emerging technologies, such as the Internet of Things (IoT) and smart packaging solutions, could also enhance functionality by enabling features like product tracking, freshness indicators, or consumer interactivity.

Despite these challenges, the trajectory of 3D printing in packaging is clear: it is moving from a niche tool to a mainstream solution. Companies that embrace it early will gain a competitive edge in innovation, agility, and sustainability. They will be able to prototype faster, launch products more quickly, and engage customers with unique, customized experiences. Importantly, they will also be better positioned to meet the growing consumer demand for eco-friendly packaging solutions. The transition may not happen overnight, but the opportunities are too significant to ignore.

In conclusion, 3D printing is transforming the packaging industry by redefining what is possible in prototyping, small-batch production, and customization. It empowers businesses to be more agile, creative, and responsive to consumer needs, while also supporting sustainability efforts. Though the technology is still evolving, its influence is already being felt across the industry, and its role will only grow in the years to come. For brands looking to stay ahead in a highly competitive market, adopting 3D printing is not just an innovative choice—it is a strategic necessity that will shape the future of packaging.