Airplane-Cut Corrugated Box with Integrated Honeycomb: A Breakthrough in Packaging Innovation

In today’s fast-paced logistics and manufacturing world, the demand for smarter, stronger, and more sustainable packaging solutions has never been higher. One such innovation gaining traction across industries, particularly in aerospace, automotive, and heavy-duty shipping, is the airplane-cut corrugated box with integrated honeycomb. This next-generation packaging system combines advanced design engineering with sustainable materials to provide unmatched protection, efficiency, and environmental responsibility.

What is an Airplane-Cut Corrugated Box?

The term airplane-cut refers to a specialized design feature in corrugated boxes where interlocking tabs or flaps are shaped similarly to airplane wings or tail fins. These flaps are precision-cut to enhance structural integrity, ease of assembly, and load distribution. The design allows for quick folding and locking, reducing the need for adhesive tapes or staples. In industrial settings, this can significantly reduce packaging time while improving consistency and durability. The airplane-cut design is particularly valuable for large or irregularly shaped items, which may require customized packaging solutions. The interlocking flaps also improve stackability, reduce movement during transport, and minimize the risk of damage.

What is Integrated Honeycomb Technology?

Honeycomb structures have long been valued in engineering and aerospace industries for their excellent strength-to-weight ratio. In packaging, integrated honeycomb refers to inserting a layer or core of honeycomb-structured material—typically made from kraft paper or cardboard—within the corrugated box walls. This creates a multi-layer protective cushion that absorbs shocks, vibrations, and impacts. The honeycomb design mimics the natural structure found in bee hives, distributing force evenly and preventing point pressure damage. When embedded into the corrugated box, it adds remarkable strength without significantly increasing weight or cost.

The Synergy: Airplane-Cut + Integrated Honeycomb

Combining the airplane-cut design with integrated honeycomb results in a packaging solution that is both mechanically resilient and operationally efficient. The synergy of these two innovations delivers a box that is:

Exceptionally strong: The honeycomb core reinforces the corrugated walls, making the box capable of withstanding high compression and impact loads.

Highly stable: The interlocking flaps reduce reliance on external fasteners and increase the box’s structural integrity.

Lightweight and eco-friendly: Despite their robustness, these boxes remain light due to the paper-based materials used, reducing shipping weight and fuel consumption.

Customizable: Both the airplane-cut design and honeycomb core can be tailored to fit specific product dimensions and weight requirements.

These benefits make this packaging type ideal for delicate, high-value items such as electronic equipment, automotive parts, aerospace components, and medical instruments.

Key Feature: No Plastic Shock-Absorbing Film

The standout feature of the airplane-cut corrugated box with integrated honeycomb is that it does not use any plastic shock-absorbing film or foam during the transportation process. This has several major benefits:

Environmentally Friendly: All components are made from recyclable paper and biodegradable adhesives.

Safe for Handling: No risk of plastic waste or chemical residue.

Lightweight Yet Durable: Honeycomb paper is extremely effective in absorbing shocks and preventing falls.

Compliance-Ready: Meets sustainability regulations and company CSR standards.

This makes it an ideal packaging choice for companies looking to reduce their environmental footprint without compromising on product safety.

Industrial Applications

Aerospace and Aviation: Aircraft parts are typically fragile, expensive, and irregular in shape. The airplane-cut corrugated box with honeycomb core provides the cushion and customization needed to safely transport these items.

Automotive Industry: Heavy engine components or glass windshields benefit from the box’s shock absorption and load-bearing capabilities.

E-commerce and Electronics: With the rise of global e-commerce, these boxes ensure that delicate electronics such as laptops, cameras, and other gadgets arrive undamaged.

Furniture and Home Appliances: For bulky or flat-packed furniture, this packaging format offers both cushioning and stackable strength.

Sustainability Benefits

A major advantage of this innovation lies in its sustainability. Made primarily from recyclable and biodegradable paper-based materials, these boxes align with modern environmental standards and circular economy goals. They can be reused multiple times and are often manufactured using water-based adhesives and non-toxic inks. This reduces environmental impact while appealing to eco-conscious brands and consumers. Additionally, reducing damage during transport means fewer returns, fewer replacement shipments, and less waste—contributing to lower carbon footprints across the supply chain.

Cost Efficiency and Scalability

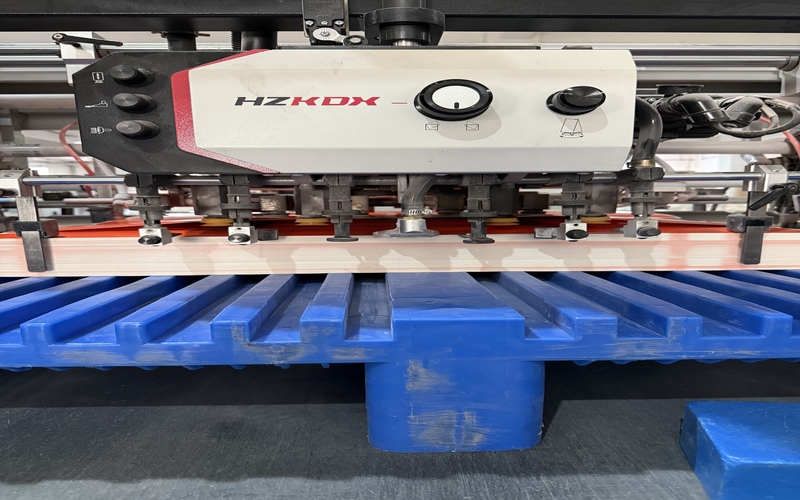

Although integrating honeycomb material and airplane-cut precision designs might seem costly initially, the long-term benefits often outweigh the upfront investment. Reduced product damage, lower labor costs due to faster assembly, and less need for protective fillers like foam or plastic make this a cost-effective solution at scale. Modern manufacturing technologies, including CNC cutting and automated assembly, have made these boxes easier to produce in large volumes with consistent quality.

Conclusion

The airplane-cut corrugated box with integrated honeycomb is more than just a packaging trend—it’s a practical response to the growing need for durable, eco-friendly, and high-performance shipping solutions. By merging engineering ingenuity with environmental responsibility, this packaging format supports industries that demand both strength and sustainability. As global supply chains evolve and green logistics become a priority, expect to see wider adoption of this innovative packaging across sectors.