The Role of Automation in Improving Print Quality and Efficiency

In the modern printing industry, rising quality expectations and tighter delivery timelines have made automation an essential part of competitive manufacturing. Automation is no longer just about increasing speed; it plays a critical role in improving print quality, consistency, and overall production efficiency. By integrating intelligent systems across pre-press, press, and post-press stages, printing companies are able to deliver higher standards while reducing errors, waste, and lead time. One of the most significant contributions of automation is consistency in print quality. Manual processes often depend on individual experience and judgment, which can lead to variations between batches. Automated workflows standardize critical parameters such as color calibration, plate alignment, ink density, and registration accuracy. Once optimal settings are established, automated systems ensure they are repeated precisely across every print job, resulting in uniform quality from the first sheet to the last.

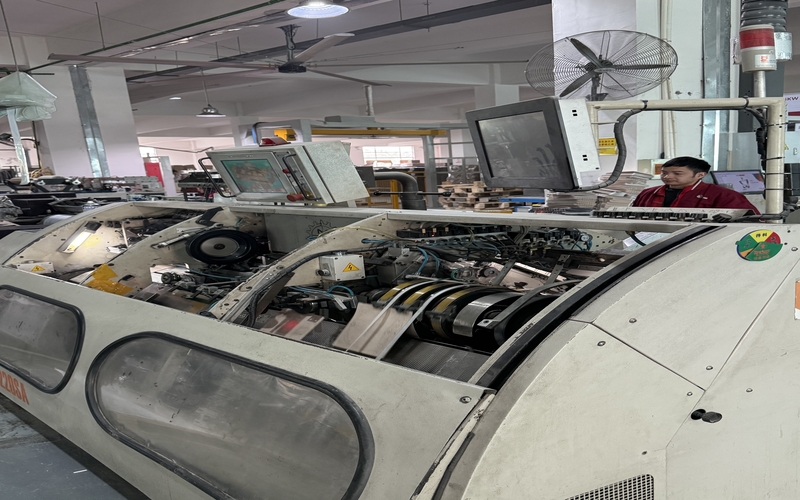

In pre-press operations, automation streamlines file preparation and error detection. Intelligent preflight systems automatically check artwork for resolution, color space, fonts, and layout issues before printing begins. This reduces the risk of costly reprints and delays caused by human oversight. Automated color management systems also ensure that digital designs are accurately translated into printed output, maintaining brand colors and visual integrity across different materials and production runs. On the press floor, automation enhances both precision and speed. Modern offset printing machines are equipped with automated plate loading, ink control, and real-time monitoring systems. Sensors continuously measure color density and register alignment, making instant micro-adjustments during the print run. This not only improves print accuracy but also minimizes setup time and material waste, allowing printers to achieve high-quality results more efficiently.

Automation also plays a vital role in reducing production waste. By quickly reaching stable print conditions and maintaining them throughout the run, automated systems significantly lower the number of rejected sheets. Reduced waste means lower material costs, improved sustainability, and more predictable production outcomes. For customers, this translates into reliable quality and better value without compromising on visual standards. Post-press processes benefit equally from automation. Automated die-cutting, folding, gluing, and inspection systems ensure that printed products are finished with precision and consistency. Vision inspection technologies can detect defects such as misalignment, color deviation, or surface damage in real time, allowing immediate corrections. This level of control ensures that only products meeting strict quality standards reach the customer.

Efficiency gains from automation extend beyond individual machines to the entire production workflow. Integrated production management systems connect equipment, scheduling, and quality control into a unified process. Real-time data allows manufacturers to optimize production planning, reduce downtime, and respond quickly to changes in order volume or design requirements. This agility is especially valuable in today’s market, where customization and shorter lead times are increasingly in demand. Automation also supports workforce development rather than replacing it. Skilled operators are empowered by intelligent systems that handle repetitive tasks, allowing them to focus on quality supervision, problem-solving, and process optimization. This combination of human expertise and automated precision results in higher overall performance and a safer, more efficient working environment.

At Wuxi Box Printing Technology Co., Ltd., automation is a core part of our commitment to quality and efficiency. With advanced offset printing machines and industry-leading intelligent pre-press and post-press equipment, we have built a highly standardized and controlled production environment. This enables us to deliver consistent, high-quality printing solutions at scale while meeting the evolving needs of our customers. Ultimately, automation is redefining what is possible in printing. By improving accuracy, reducing waste, and accelerating production, it allows brands to achieve superior print quality without sacrificing efficiency. As technology continues to advance, automation will remain a driving force behind innovation, reliability, and excellence in the printing and packaging industry.