Digital Transformation in Printing: Embracing Smart Manufacturing

Digital transformation is reshaping industries across the world, and the printing and packaging sector is no exception. As customer expectations rise and market competition intensifies, traditional production methods alone are no longer enough to meet the demands for speed, precision, flexibility, and sustainability. Embracing smart manufacturing has become a strategic necessity for forward-thinking printing companies, and it is a direction that is redefining how modern printing operates, evolves, and delivers value to brands. Smart manufacturing in printing begins with the integration of digital technologies into every stage of production. From order management and design processing to printing, finishing, inspection, and delivery, digital systems allow information to flow seamlessly across the entire workflow. This connectivity reduces manual interventions, improves communication between departments, and eliminates many of the delays and errors commonly seen in traditional production models. When information is stored and transferred digitally, every process becomes faster, more accurate, and more transparent.

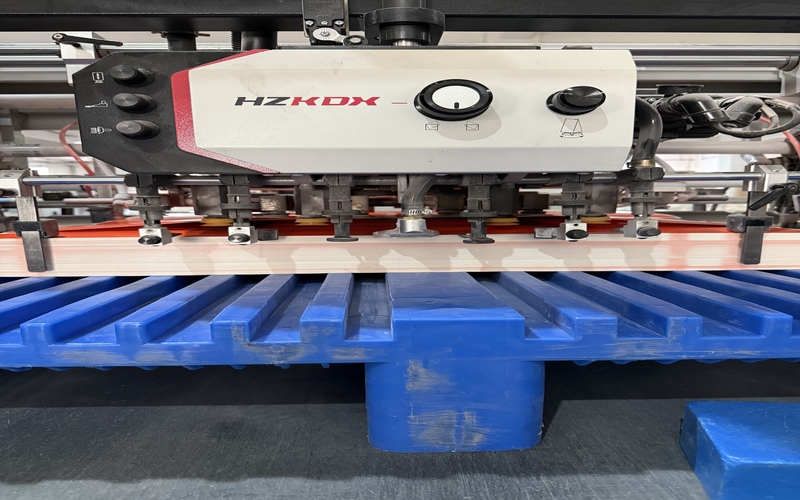

Automation plays a central role in this transformation. Advanced printing equipment equipped with intelligent control systems can automatically adjust parameters such as ink density, alignment, speed, and pressure based on real-time data. These adjustments ensure optimal performance and consistent output quality, even during large or complex production runs. Automation also reduces the dependence on manual operation for repetitive tasks, allowing skilled workers to focus more on quality control, innovation, and problem-solving. The use of data is another powerful aspect of smart manufacturing. Every print job generates valuable information about machine performance, material usage, color consistency, and production efficiency. By collecting and analyzing this data, printing companies can identify patterns, optimize workflows, reduce waste, and make smarter decisions for future projects. Predictive maintenance, for example, uses data from machines to detect early signs of wear or malfunction, helping prevent unexpected breakdowns and costly downtime. This proactive approach improves equipment reliability and extends machine lifespan.

Digital transformation also enhances customization and flexibility. Modern brands want packaging that reflects their unique identity, and they often require short production runs with customized designs. Smart manufacturing systems make it possible to switch between jobs quickly, adjust settings instantly, and process multiple design variations without sacrificing quality. This flexibility allows printing companies to better serve small businesses, limited-edition products, and personalized packaging requests, which are becoming increasingly popular in today’s consumer market. In the context of high-end packaging, precision and consistency are crucial. Smart manufacturing systems use advanced color management and calibration tools to ensure exact color replication across all print runs. When a brand introduces a specific shade for its logo or packaging, that color must remain consistent in every batch, regardless of quantity or production date. Digital control ensures that once a color profile is set, it can be repeated with exceptional accuracy, strengthening brand identity and eliminating variations that could damage customer trust.

Another important aspect of digital transformation is its impact on sustainability. Intelligent production planning reduces material waste by optimizing layouts, minimizing setup errors, and improving alignment accuracy. Energy monitoring systems help reduce power consumption by identifying inefficient operations and enabling better resource management. With the help of digital tools, companies can move toward more environmentally responsible production models while maintaining high levels of productivity and profitability.

The transformation is not limited to machinery alone; it also involves people and culture. Employees must adapt to new technologies and develop digital skills to operate advanced equipment and analyze complex data. Continuous training and education become essential, turning workers into highly skilled technicians and digital specialists. This shift in skill requirements not only improves operational efficiency but also creates a more innovative, adaptable, and future-ready workforce. Smart manufacturing also strengthens communication with customers. Digital systems provide real-time updates on production status, timelines, and quality checkpoints. This transparency builds trust and improves collaboration between the printing company and its clients. Customers can make adjustments, confirm approvals, and track progress more efficiently, resulting in smoother project execution and higher satisfaction.

In a rapidly changing global market, the printing industry must evolve to remain competitive. Embracing digital transformation is no longer just an option — it is a long-term strategy for survival and growth. Through automation, data intelligence, connectivity, and innovation, smart manufacturing is setting new standards for quality, efficiency, and sustainability. By investing in advanced equipment, intelligent systems, and skilled professionals, forward-looking printing companies are not only improving their internal operations but also empowering their customers to succeed. Digital transformation is shaping the future of printing into a more agile, accurate, and intelligent industry, ready to meet the challenges and opportunities of tomorrow.