How to Customize an Extra Thick Book with 3022 Pages

We are a factory of customized paper products, paper box and some business printing such as calendars, product manuals, books and so on.

Today to introduce, how we to customize books, the process is very simple, determine the file, printing, cover in addition to laminating, the inner pages do not need to laminating, and then glued, and finally die-cutting. These steps are more conventional, each factory is similar. The difference is that the difference in the customized products.

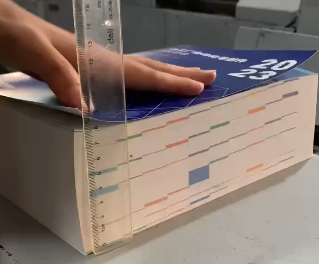

One of our customers need to customize more than 3000 pages of product manuals, so many pages of the book is very rare, the thickness of a sheet of paper is not thick, but more than 3000 pages thickness will be very thick, and the customer also wants us to customize the thinner, so that it is easy to read, transportation, as well as cost savings.

We looked for a 56g coated paper according to the customer's requirements, very thin, general books do not recommend using this paper, very soft, but very much in line with the 3022 pages of the book, the cover we also used a soft cover, also coated paper, that is, it will be a little thicker than the inner pages, this can not be too thin, easy to be damaged.

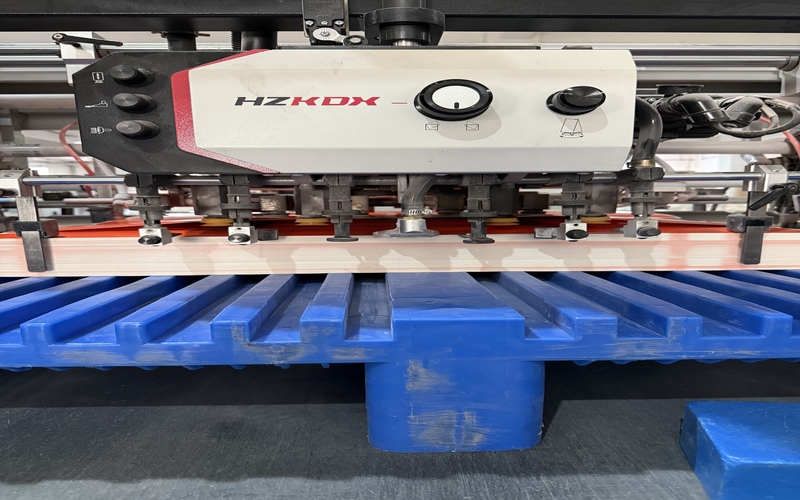

After all, it is a very thick book, we suggest that the side to add a retrieval strip, can be convenient to read, the customer listened to this suggestion is very satisfied, the back is the normal start of production, four-color printing, and then to the gluing of this step, we are also strict control of the content of the glue, can not be too much, or else the finished product out of the bad page. Each step we do very strict, the process is also constantly testing.

After the final production is completed, the overall thickness in 7.8cm, as expected, the customer is very satisfied!