The Technology of “Coated Kraft Cardboard” or “Coated Kraft Paperboard”

Its technology revolves around the process of applying a specialized coating to a strong kraft base sheet to enhance its printability and appearance while maintaining its inherent strength.

The key technological areas are as follows:

1. Base Stock – Kraft Linerboard Technology

The quality of the base kraft paper is fundamental.

· Strength Properties:

· Ring Crush Test (RCT): Measures edgewise compression strength, critical for box stacking ability.

· Bursting Strength: Resistance to rupture under pressure, indicating durability during handling and shipping.

· Tear Resistance: The force required to propagate a tear in the paper.

· Surface Properties:

· Smoothness and Porosity: The surface must be uniform. A too-rough surface requires excessive coating, increasing cost and potentially reducing flexibility.

· Surface Absorbency: Must be carefully controlled. High absorbency causes the coating to penetrate too deeply, reducing gloss and print quality. Low absorbency can lead to poor coating adhesion.

· Uniformity: The basis weight, thickness, and moisture content must be highly consistent across the entire sheet to avoid uneven coating and print mottling.

2. Coating Formulation Technology

This is the "core recipe" and a highly proprietary aspect of manufacturing.

· Pigments (70%-90% of the coating):

· Kaolin (Clay): Provides whiteness, smoothness, and gloss.

· Precipitated Calcium Carbonate (PCC) / Ground Calcium Carbonate (GCC): Enhances whiteness, opacity, and ink absorbency; also a cost-effective filler.

· Titanium Dioxide (TiO₂): Provides extreme opacity and brightness for premium-grade products.

· Binders:

· Styrene-Butadiene Latex (SBR), Starch, Polyvinyl Alcohol (PVA). Their function is to bind the pigment particles together and firmly adhere the coating layer to the kraft base. The type and amount directly affect the coating's strength, water resistance, and printability.

· Additives (Small dosages, significant impact):

· Dispersants: Ensure pigments remain uniformly suspended in the coating slurry.

· Rheology Modifiers: Control the flow and viscosity of the coating for optimal runnability on the coater.

· Water Resistance Agents: (e.g., Alkyl Ketene Dimer - AKD) to improve the coating's holdout against moisture.

· Lubricants: (e.g., Calcium Stearate) to enhance smoothness and abrasion resistance.

· Optical Brightening Agents (OBA): To increase the perceived whiteness and brightness.

3. Coating Application & Process Technology

This is the engineering of applying the coating uniformly. The primary methods are:

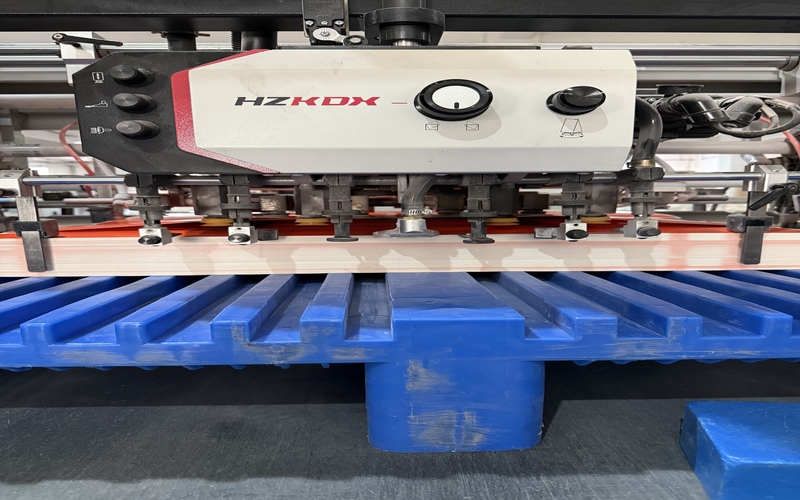

· Blade Coating: The dominant technology for high-quality surfaces. A flexible steel blade meters the coating, resulting in a very uniform, smooth, and high-gloss surface. It demands high precision and a consistent base sheet.

· Stiff Blade Coating: Used for the highest gloss and smoothness.

· Flexible Blade Coating: Offers better coverage and is more forgiving of variations in the base sheet.

· Air Knife Coating: Uses a high-pressure air stream to meter the coating. It applies a thicker layer, good for coverage, but generally produces a lower surface smoothness compared to blade coating.

4. Drying & Finishing Technology

· Drying: After application, the wet coated web passes through a drying section (e.g., infrared, hot-air hoods, steam-heated cylinders). The drying profile must be precisely controlled to prevent coating cracking, blistering, or picking.

· Calendering / Supercalendering:

· Calendering: The paper is passed through a stack of heavy rollers (nips) to increase its smoothness and gloss.

· Supercalendering: Uses an alternating stack of hard steel rolls and soft polymer rolls under high pressure and heat to produce a mirror-like, high-gloss finish used for luxury packaging.

5. Quality Control & Testing

The final Coated Kraft Cardboard is subjected to rigorous testing:

· Printability: Including Ink Absorbency, Pick Resistance (surface strength), and Print Gloss.

· Brightness & Opacity.

· Smoothness & Gloss.

· Strength Properties: Ensuring the core strength (RCT, Burst) has not been compromised by the coating and calendering processes.

Key Technical Trends

1. Sustainability: Developing coatings with more bio-based/bio-degradable binders, recycled pigments, and reducing the overall environmental footprint.

2. Lightweighting: Developing stronger base kraft sheets with lower basis weight to reduce material usage and shipping costs without sacrificing performance.

3. Functional Coatings: Adding specific functionalities, such as:

· Water & Grease Resistance: For cold chain or food packaging.

· Anti-static Properties: For electronics packaging.

· Barrier Coatings: To provide resistance to moisture vapor, oxygen, or aromas.

In summary, the technology of Coated Kraft Cardboard is a sophisticated integration of material science, chemical engineering, and precision mechanical processes. It transforms a robust, utilitarian material into a premium substrate that meets the dual demands of structural integrity and high-impact visual appeal in modern packaging.