Why Structural Packaging Design Matters More Than Ever

In today’s fast-changing marketplace, packaging is no longer judged by appearance alone. While visual design remains important, the structure of packaging has become just as critical—if not more so—in shaping customer experience, protecting products, and supporting brand growth. Structural packaging design refers to the physical form of a package: its shape, strength, opening method, material efficiency, and how it performs throughout the supply chain. As consumer expectations rise and distribution channels become more complex, structural design matters more than ever. One of the most important reasons structural packaging design has gained prominence is the growth of e-commerce and long-distance logistics. Products are no longer simply placed on retail shelves; they are shipped, stacked, handled repeatedly, and delivered to customers’ doors. Poor structural design can result in damaged products, increased returns, and negative brand perception. Well-engineered packaging ensures durability and protection, absorbing impact and resisting pressure during transportation. A strong structure gives customers confidence that the brand cares about quality from start to finish.

Structural design also directly affects user experience. How a box opens, how easily a product can be removed, and whether the packaging can be reused or stored all influence how customers feel about the brand. Packaging that is difficult to open or awkward to handle can create frustration, even if the product itself is excellent. On the other hand, smart structural features such as tear strips, magnetic closures, or intuitive folding mechanisms create a smooth and satisfying interaction. These small details enhance perceived value and leave a lasting impression on the customer. Efficiency and cost control are another key reason structural packaging design is more important than ever. Well-designed structures use materials more efficiently, reducing waste without compromising strength. Optimized dielines and right-sized packaging help lower raw material costs and reduce shipping expenses by minimizing empty space. In an era where sustainability and cost management are top priorities, efficient structural design allows brands to achieve both goals at once.

Sustainability is closely linked to structure. Consumers and regulators increasingly expect packaging to be environmentally responsible. Structural design plays a major role in reducing environmental impact by eliminating unnecessary layers, simplifying components, and enabling recyclability. A thoughtfully engineered box can replace plastic inserts, reduce overall material usage, and support the use of FSC-certified or recyclable paper. By focusing on structure, brands can meet sustainability goals while maintaining premium quality and performance. Structural design also supports brand differentiation. In crowded markets, a unique box shape or opening experience can instantly set a product apart. When consumers encounter packaging that feels different—more solid, more elegant, or more convenient—it reinforces brand identity. Structural innovation becomes a silent brand ambassador, communicating creativity, care, and professionalism without saying a word. For gift boxes, beauty products, electronics, and specialty foods, structure is often a defining element of brand personality.

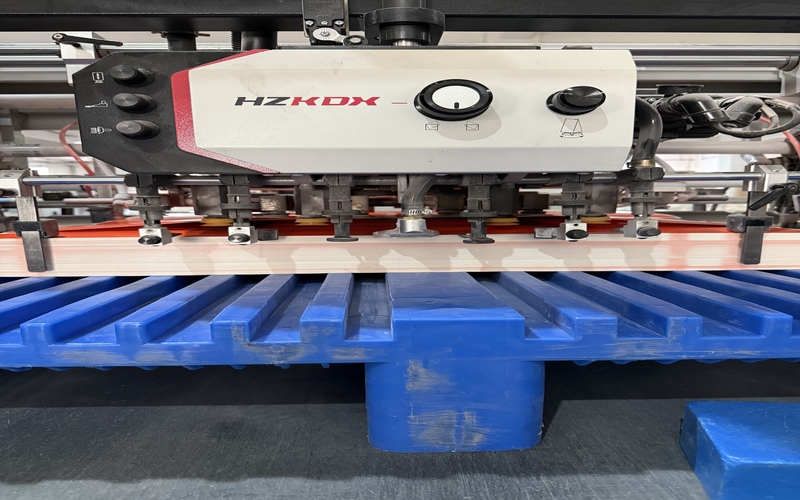

From a production perspective, good structural design improves manufacturing efficiency and consistency. Packaging that is designed with production in mind runs more smoothly on printing, cutting, folding, and gluing equipment. Poorly designed structures can lead to production delays, higher defect rates, and increased labor costs. At Wuxi Box Printing Technology Co., Ltd., structural design is developed alongside printing and finishing processes to ensure smooth mass production and stable quality. This integrated approach helps customers scale their packaging needs with confidence. Structural packaging design also plays a vital role in regulatory compliance, especially in industries such as food, pharmaceuticals, and healthcare. Packaging must protect products from contamination, maintain integrity, and display required information clearly. Structural stability ensures that labels remain legible, seals remain intact, and products stay safe throughout their shelf life. This reliability builds trust with both regulators and consumers.

Ultimately, structural packaging design is no longer an afterthought—it is a strategic decision that affects cost, sustainability, customer satisfaction, and brand reputation. As markets become more competitive and consumer expectations continue to rise, brands that invest in smart structural design gain a clear advantage. They reduce risk, improve efficiency, and deliver a better overall experience. At Wuxi Box Printing Technology Co., Ltd., we understand that strong packaging starts with strong structure. By combining professional structural engineering, advanced printing technology, and intelligent manufacturing systems, we help brands create packaging that performs as beautifully as it looks. In a world where packaging must do more than ever before, thoughtful structural design has become essential—and we are proud to help our customers lead the way.