How We Handle Rush Custom Orders—Custom Baking Tool Boxes for a US Client

At 5:00 PM on January 21st, a buyer from the US specializing in baking tools sent an email inquiring about our fastest possible delivery time. He urgently expressed his need for these paper boxes to package his baking mats and other products, as his baking tools were already completed and the shipping deadline was approaching. He hoped the goods could be transported to his freight forwarder by February 1st.

Upon receiving this information, we promptly verified production schedules and shipping logistics. We clearly confirmed to the client that we could accommodate this timeline. Provided the print-ready files were submitted, we could expedite this custom order for shipment on February 1st.

Around 11:00 AM on January 21st, we continued discussions with the client, confirming an initial order of two box styles, 5,000 units each. The client simultaneously sent over the design files. By 6:00 PM, we provided a quotation, which the client accepted without objection.After 10 PM on January 21st, we prepared the payment order, Proforma Invoice (PI), and other documents for the client. Before 11 PM, the client completed payment—an exceptionally swift transaction.

The next business day, the client inquired about another urgent order: 5,000 envelope bags for shipping their baking tools. We confirmed availability and processed the order. After payment was received, we forwarded the client's design files to our prepress department for verification. The files were found to be non-vector format, requiring the client to provide source files. The client wasn't very familiar with this process, so we needed to spend some time handling it. After processing the files, we reconfirmed with the client. Once everything was verified, we sent the files to the production department for printing. Since we had modified the files, the production team printed a sample as a precaution, asking our sales staff to review it for accuracy.

On January 26th, after confirmation, the production department proceeded with bulk printing. Our Heidelberg 7-color press has seven printing units, so this volume was manageable and completed within one day.

To set the ink, the sheets were air-dried naturally on January 27th.

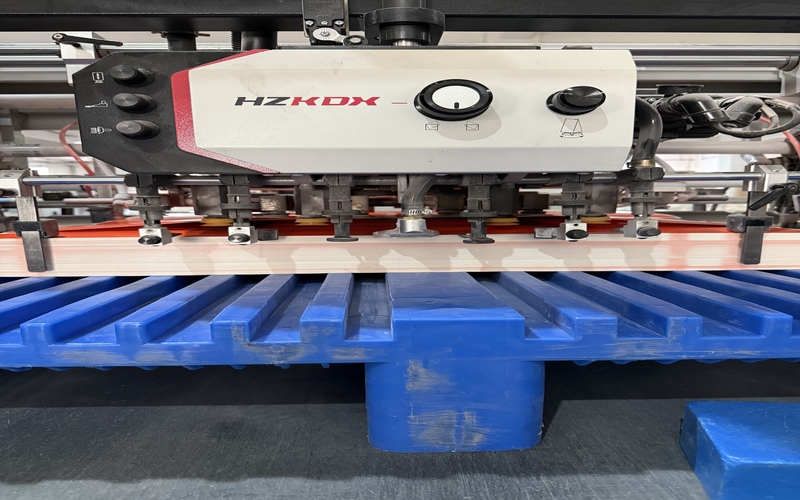

On January 28th, they moved to the post-press workshop for lamination, which was completed within a day.

On January 29th, the job was scheduled for die-cutting.

On January 30th, it underwent folding, gluing, quality inspection, and packaging on an integrated machine. While maintaining high efficiency, we ensured production quality with no fewer than three quality inspections throughout the process.

We are now awaiting the company's unified logistics arrangements for shipment on February 1st.

On January 28th, six additional clients requested shipment before the Chinese New Year holiday. We have made appropriate arrangements for each based on their product specifications and production schedules. Our production machinery and staff are currently working diligently to meet these demands. We remind everyone that international logistics operations will largely conclude around February 10th, with some freight forwarders ceasing to accept new orders after February 8th. Please coordinate with us promptly according to your requirements.