How We Ensure Color Accuracy Across Every Print Job

Color consistency is one of the most critical elements in professional printing, especially for brands that rely on strong visual identity and high consumer trust. At Wuxi Box Printing Technology Co., Ltd., achieving perfect color accuracy is not just a technical pursuit—it is a promise to our customers. Every hue, tone, and gradient printed on our folding cartons, gift boxes, labels, and commercial materials reflects our commitment to excellence. In a competitive market where packaging often forms the first impression, accurate color reproduction becomes a key factor in brand recognition and consumer loyalty. Our color accuracy begins long before the printing presses start running. We place significant emphasis on the pre-press stage, where files are checked, calibrated, and processed through advanced color management systems. Our intelligent pre-press technology ensures that digital files match the expected output, minimizing discrepancies between on-screen designs and final printed products. Equipped with industry-leading software and color proofing tools, our team makes sure that designers, brand owners, and production specialists all align on a unified color standard before entering mass production.

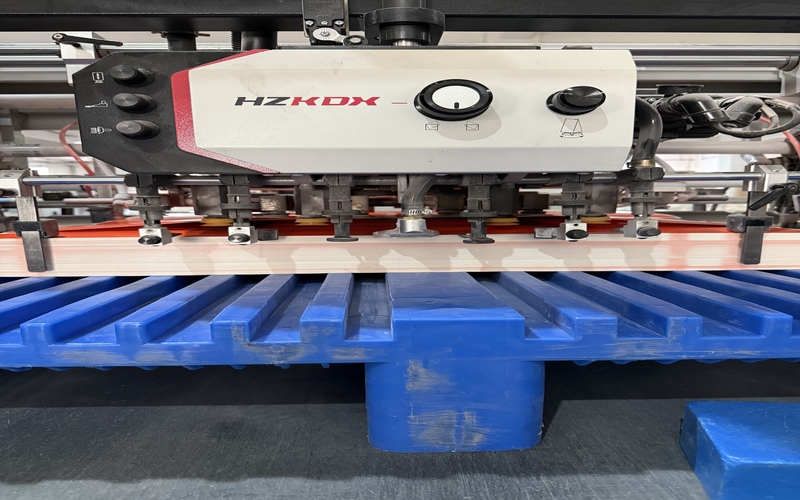

Once the design is finalized, our printing equipment becomes the next crucial element in achieving color precision. Wuxi Box Printing operates 12 world-class offset printing machines from Heidelberg, Roland, and Komori—brands widely regarded for their exceptional color stability and printing accuracy. These machines are calibrated regularly using international printing standards, ensuring that each batch, whether small-volume or high-volume, maintains consistent color across all units. Even subtle variations can affect a customer’s brand perception, so we make it our mission to eliminate these variations from the very beginning. Color accuracy is also strengthened through our standardized processes. We have built a comprehensive quality control system based on product standardization, process standardization, and strict color management. This system ensures that every step—from plate-making and ink preparation to printing, drying, and post-press finishing—follows strict quality protocols. Standardization prevents deviations caused by environmental factors, machine conditions, individual operations, or raw materials, ensuring that the final printed result is stable and predictable every time.

One of the most important roles in maintaining color consistency is played by our professional technical team. More than 30% of our workforce consists of experienced technical personnel who understand the complexities behind color science, ink behavior, paper absorption, and machine calibration. Their expertise enables us to identify potential issues early and adjust settings precisely to achieve the desired results. In an industry where a small misalignment can cause major visual discrepancies, the skills of our team form a vital part of our quality foundation.

Material selection is another key factor in achieving accurate and consistent color reproduction. Different papers, coatings, and substrates absorb ink differently, resulting in variations in brightness, saturation, and texture. Our team conducts thorough testing and provides professional consultation to help customers choose the most suitable materials for their packaging or print products. Whether it is high-end gift box paperboard, pharmaceutical-grade packaging materials, or eco-friendly FSC-certified paper, we ensure that the chosen substrate supports both aesthetic quality and color precision.

In addition to internal controls, we also rely on internationally recognized certifications to verify our quality standards. With ISO9001, RoHS, CE, FSC, and EPR certificates, Wuxi Box Printing demonstrates that our production processes meet global expectations on quality, safety, sustainability, and color management. These certifications not only strengthen the credibility of our products but also assure customers that their brand colors will remain accurate regardless of order size or application. To further ensure accuracy, we implement strict on-site inspections throughout the printing process. Our machines are equipped with real-time color monitoring systems that detect inconsistencies and allow immediate adjustments. Finished samples are compared with approved color proofs under standardized lighting conditions to confirm that all prints meet the customer’s expectations. This approach helps us maintain tight control from the first printed sheet to the last, ensuring uniformity across the entire batch.

Ultimately, color accuracy is more than a technical requirement—it is a strategic asset for our customers. Brands in industries such as food, cosmetics, pharmaceuticals, and consumer goods rely on consistent color to create strong shelf presence and build emotional connection with consumers. When packaging colors shift even slightly, it can affect brand trust, confuse customers, or weaken product impact. By delivering highly accurate and consistent color across every print job, Wuxi Box Printing ensures that brands maintain their visual power in every market. Through advanced technology, world-class equipment, skilled professionals, standardized processes, and strict quality control, we guarantee color accuracy for every project. Our goal is simple: to help customers present their brands with confidence, clarity, and unmistakable identity. Color is more than an element of design—it is a promise, and we make sure that promise is kept with every print.