Detailed Process for Customizing Packaging Cartons By Wuxi Box Printing Technology

In today’s competitive business landscape, packaging is more than just a container—it’s a reflection of your brand identity, product quality, and customer experience. At Wuxi Box Printing Technology, we understand that customized packaging cartons do more than protect the product—they communicate value, engage buyers, and drive brand recognition. Customizing a packaging carton is not a one-size-fits-all task; it involves a detailed process that requires strategic planning, design expertise, and precision execution.

Step 1: Understanding the Product and Its Needs

The first and most crucial step in customizing a packaging carton is understanding the product it will house. Our team at Wuxi Box Printing Technology begins by assessing the product's dimensions, weight, fragility, and nature. Whether it's a delicate electronic item, a luxury cosmetic, or a boxed food product, each product has its own set of requirements. This evaluation ensures the packaging is both protective and practical, while also laying the groundwork for the design and material selection.

Step 2: Gathering Branding Requirements

Once the product specifications are established, we move on to understanding the brand's visual and communication goals. Our clients provide us with brand guidelines, logos, preferred color schemes, and any text or graphics that need to be included. This stage is vital in aligning the packaging with the client’s branding strategy. At Wuxi Box Printing Technology, we emphasize consistency in brand messaging across every packaging element to maintain a unified and recognizable brand identity.

Step 3: Selecting the Right Material

The choice of material is critical in the customization process. Depending on the product type and branding needs, we offer a wide range of carton materials—from eco-friendly kraft paperboard and corrugated fiberboard to premium coated or laminated stocks. We also consider functional factors such as moisture resistance, recyclability, and durability. The material selection at Wuxi Box Printing Technology is not just about aesthetics—it’s about matching form with function to achieve optimal performance.

Step 4: Designing the Structure and Style

Structural design involves deciding the shape, opening style, and any special features the box may need. Should it have a magnetic closure? Does it need a window cutout to showcase the product? Will it be a tuck-end box, sleeve box, or a folding carton? Our packaging engineers use CAD software and 3D mockups to design a carton that is both visually appealing and structurally sound. At this stage, we work closely with our clients to ensure the carton style complements both the product and the customer experience.

Step 5: Graphic Design and Print Proofing

After the structural design is finalized, our graphic designers lay out the visual elements on a dieline template. This includes logo placement, typography, color usage, and any required legal information or barcodes. We then produce a digital or physical print proof for approval. At Wuxi Box Printing Technology, we encourage our clients to review the proof carefully, as this step ensures that the final print run will meet their expectations.

Step 6: Sample Creation and Testing

Before moving to full production, we create a physical sample of the custom carton. This sample undergoes a series of quality and functionality tests such as drop tests, stacking pressure analysis, and usability evaluation. This step is essential in identifying any potential issues early in the process. It also allows the client to see and feel the final product before large-scale printing begins. Our commitment to quality control ensures that nothing is left to chance.

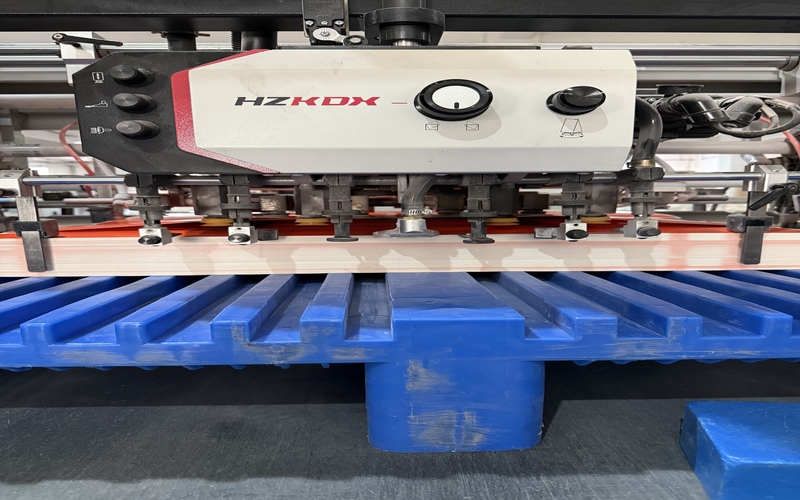

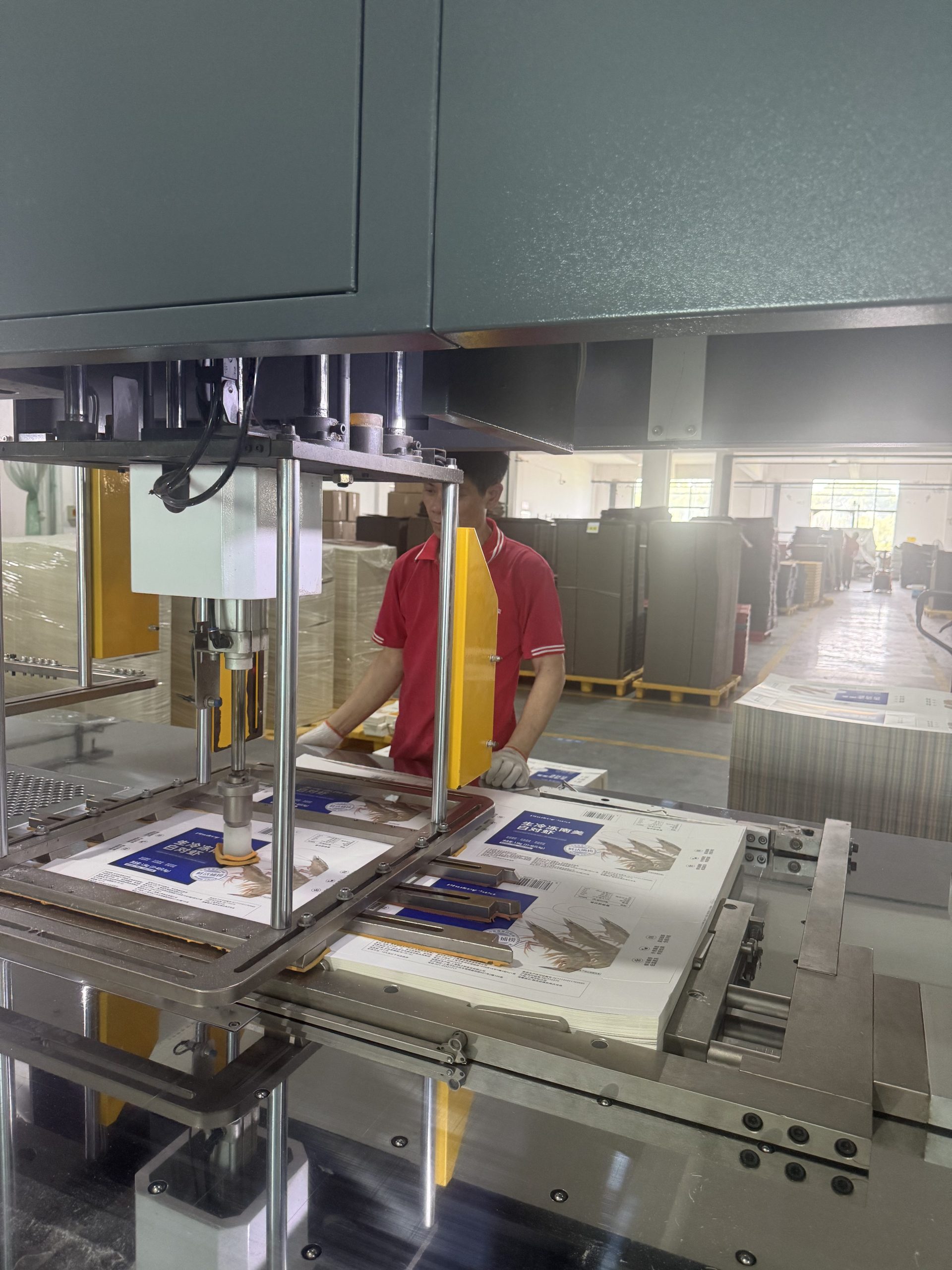

Step 7: Mass Production and Quality Assurance

Upon sample approval, we proceed to mass production using high-end printing presses and automated carton assembly equipment. Whether the client has chosen digital, offset, or flexographic printing, we ensure consistent print quality throughout the entire run. Our production team monitors every stage, from color consistency to cutting precision and folding accuracy. At Wuxi Box Printing Technology, every packaging carton goes through strict quality assurance checks before being cleared for delivery.

Step 8: Packing, Delivery, and Support

Once production is complete, the cartons are packed carefully and prepared for shipment. We offer flexible delivery solutions based on the client’s timeline and logistics requirements. Even after delivery, our support team remains available for any follow-up, including future reorder planning or design tweaks for new products. Our comprehensive customer service ensures that every client has a smooth and satisfactory experience from start to finish.

Conclusion: Crafting Custom Packaging That Performs

Customizing packaging cartons is a detailed and collaborative process that requires technical skill, creativity, and industry knowledge. At Wuxi Box Printing Technology, we don’t just deliver boxes—we deliver tailored packaging solutions that protect, present, and promote your product. From concept to creation, every step in our process is designed to ensure that your custom packaging aligns perfectly with your product and brand vision.